Production process

Production process

The professional performance testing laboratory is equipped with multi-function universal testing machine, advanced ozone high and low temperature aging box, multi-function colorimeter, salt spray testing machine, German Nix coating thickness gauge, weather resistance and corrosion resistance test box, self-designed fatigue testing machine and other modern testing equipment to ensure product performance to meet customer needs.

1, equipment: the use of automatic profile blanking equipment, high degree of automation; 2. High precision: blanking size deviation ± 0.1; 3, high stability: repeat positioning accuracy control in ± 0.05; 4. High efficiency: at the same time, the maximum number of blanking is 20.

1. Equipment: full-automatic bending equipment is adopted, with accuracy: bending size deviation ± 0.5mm; High stability: repeated bending size deviation ± 1mm. 2. Process: aluminum profile filling and bending process is adopted to perfectly solve the problem of bending collapse and folding of aluminum profile. 3. Efficiency: 3 sets of bending equipment have a production capacity of 600 pieces/day (100 pieces/day for a single set, double shifts)

1. Equipment: full-automatic plastic spraying assembly line, equipped with golden horse spray gun imported from Switzerland, to ensure uniform plastic spraying on the surface of the product when the film thickness is 80μm-120μm. 2. Efficiency: The daily production capacity of the plastic spraying assembly line is 1000 pieces/day.

1. Equipment: laser cutting equipment 2. High stability: repeated positioning accuracy: ± 0.05mm/1000mm; 3. High precision positioning accuracy: ± 0.1mm/1000mm; 4. Efficiency: Two laser blanking equipment can meet the production capacity of 200 sets/day at the same time.

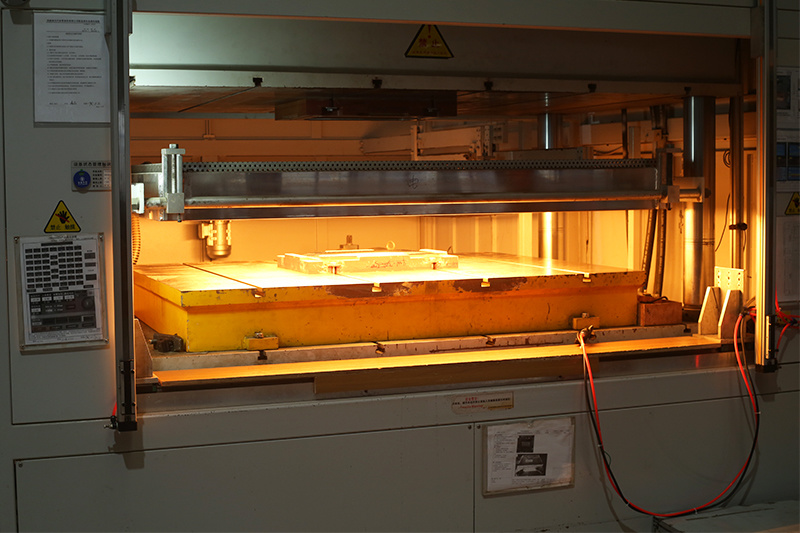

1. Equipment: multiple hot pressing molding equipment to ensure the molding of acrylic sheets of various sizes. 2. Process: Hot pressing over-molding equipment can realize precise temperature control for different products and different pressing contours; 3. Efficiency: It can meet the production capacity of 200 sets/day.

1, the environment: the construction of a clean 100000 level dust-free workshop; 2. Equipment: full-automatic gluing equipment and glass bonding light solid assembly line; 3, high quality; the use of special glass bonding tooling, effectively ensure product consistency; 4. Efficiency: It can meet the production capacity of 150 sets/day.

1. Equipment and tooling: CNC high-precision milling machine is used, and special tooling is used for glass cutting to ensure the stability of product size. Four-edge round corner milling cutter is used, and the appearance is beautiful after glass cutting; 2. It can meet the production capacity of 120 sets/day.

1. High quality assurance: 100% full inspection after the final assembly of the product; 2. Personnel: After skill training, they will take up their posts after passing the evaluation; 3. Efficiency: It can meet the production capacity of 300 sets/day.

Henan Zhuoer Auto Parts Co.,ltd.

No. 777, Intersection of Junction No.8 Road and Lugang No.1 Road, liangyuan district District, Shangqiu City, Henan Province

If you need to inquire about our products or price list, please contact us, we will contact you within 24 hours.

Copyright©2024 Henan Zhuoer Auto Parts Co., Ltd.

powered by: www.300.cn | Tags